Constellium, a leading aluminium products producer, announced that it has completed its first industrial-scale hydrogen casting at C-TEC, Constellium’s primary R&D center. This casting was performed in a 12-ton furnace following strict internal procedures and quality monitoring including the use of Batscan™ technology used to detect inclusions in molten aluminum.

“We are thrilled to announce the successful completion of our first industrial-scale hydrogen casting. Utilising hydrogen as a substitute for natural gas not only demonstrates our commitment to sustainability but also paves the way for future innovations in green technologies,” said Ludovic Piquier, Senior VP, Manufacturing Excellence and Chief Technical Officer of Constellium.

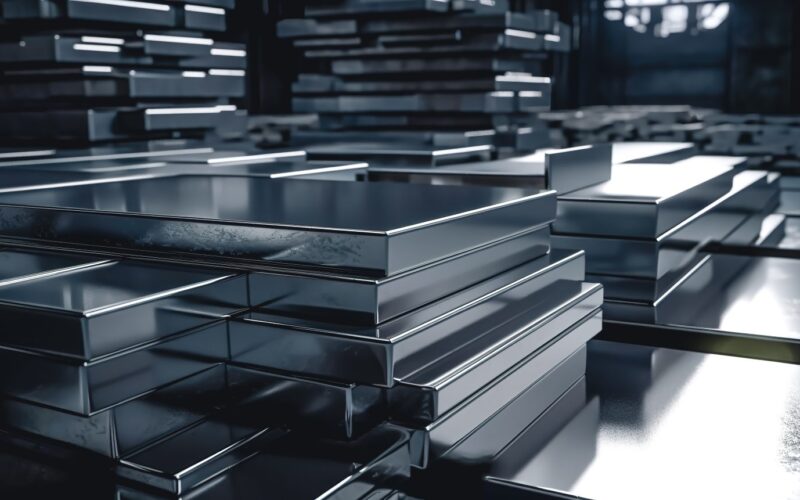

The 12-tonne aluminium slab produced through hydrogen casting will undergo further processing at Constellium’s Neuf-Brisach facility in France, for use in electric vehicles. Constellium has also started exploring hydrogen’s performance as a potential substitute for natural gas at an industrial scale as it is green, accessible, and cost-effective.

Constellium is actively engaged in several multi-stakeholder projects aimed at advancing hydrogen technologies for industrial decarbonisation. The company participates in HyInHeat (“Hydrogen technologies for decarbonization of industrial heating processes”), an EU-funded initiative exploring hydrogen’s substitution for natural gas in aluminium and steel processing.