Researchers at the Hong Kong University of Science and Technology (HKUST) have unveiled the world’s first kilowatt-scale elastocaloric cooling device. Capable of stabilising indoor temperatures at 21-22°C within 15 minutes, even in outdoor conditions of 30-31°C, this innovation paves the way for commercial applications of elastocaloric solid-state cooling technology. The findings, published in journal Nature, offer a promising path towards reducing carbon emissions and transforming the global cooling industry.

With global warming intensifying, the demand for cooling solutions is rising rapidly. Currently, cooling accounts for 20% of global electricity consumption, with mainstream vapour compression cooling technology relying on high global warming potential (GWP) refrigerants. In contrast, elastocaloric cooling technology, based on shape memory alloys (SMAs), produces zero greenhouse gas emissions and offers high energy efficiency, attracting significant interest from researchers and industry.

Despite its potential, elastocaloric cooling has faced limitations in scale. Previous devices could only achieve a maximum cooling power of 260 watts—far below the kilowatt-level required for commercial air conditioning. The HKUST team, led by Professors Sun Qingping and Yao Shuhuai from the Department of Mechanical and Aerospace Engineering (MAE), identified two key obstacles: balancing the specific cooling power (SCP) of the refrigerant with the total active mass and improving heat transfer efficiency during high-frequency operation.

To overcome these challenges, the team introduced a pioneering “SMAs in series – fluid in parallel” multi-cell architecture. This design connects ten elastocaloric cooling units in series, with each unit containing four thin-walled nickel-titanium alloy tubes, optimising heat exchange efficiency through a high surface area-to-volume ratio of 7.51 mm⁻¹. The system operates at a stable pressure below 1.5 bar, ensuring reliable high-frequency performance.

A key innovation in this research is the replacement of distilled water with graphene nanofluid, a cutting-edge heat transfer medium. Experimental results show that at a concentration of just 2 grams per litre, graphene nanofluid enhances heat conductivity by 50% compared to distilled water. The nanoparticles, measuring just 0.8 micrometres, are significantly smaller than the 150-500 micrometre-wide fluid channels, reducing blockage risks.

X-ray tomography confirmed that the nickel-titanium tubes maintained uniform compressive deformation under a stress of 950 megapascals without buckling failure. Operating at a high frequency of 3.5 Hz, the device achieved an SCP of 12.3 W/g and a total cooling power of 1,284 watts, demonstrating real-world applicability.

In practical application tests, the device successfully cooled a 2.7 m³ model house in summer outdoor temperatures of 30-31°C, maintaining an indoor temperature of 21-22°C within just 15 minutes.

Compared with existing solid-state cooling technologies, this innovation leads in both cooling power and temperature lift. Its SCP value of 12.3 W/g is nearly three times the previous record for liquid heat transfer elastocaloric devices (4.4 W/g) and represents the first successful breakthrough beyond the kilowatt-scale cooling threshold.

Commenting on the breakthrough, Prof. Sun Qingping said, “This achievement demonstrates the potential for large-scale adoption of elastocaloric cooling technology. We are working closely with industry partners to accelerate its commercialisation. As global regulations on hydrofluorocarbons (HFCs) tighten, this zero-emission, energy-efficient cooling technology could revolutionise the air conditioning industry while lowering energy costs for consumers.”

Prof. Yao Shuhuai added, “Further improvements in elastocaloric materials and system design could enhance performance, enabling even faster cooling for indoor environments.”

This milestone marks another major success for the HKUST research team within a year. It builds upon their earlier development of a multi-material elastocaloric device that set a record 75K temperature lift, published in Nature Energy in 2024. Their latest paper, “Achieving Kilowatt-Scale Elastocaloric Cooling by a Multi-Cell Architecture”, is now featured in Nature.

The research was supported by the Strategic Topics Grant (STG), General Research Fund (GRF), Innovation and Technology Commission (ITC), and National Natural Science Foundation of China, among others. Multiple international patents have been filed, and commercialisation efforts are progressing rapidly.

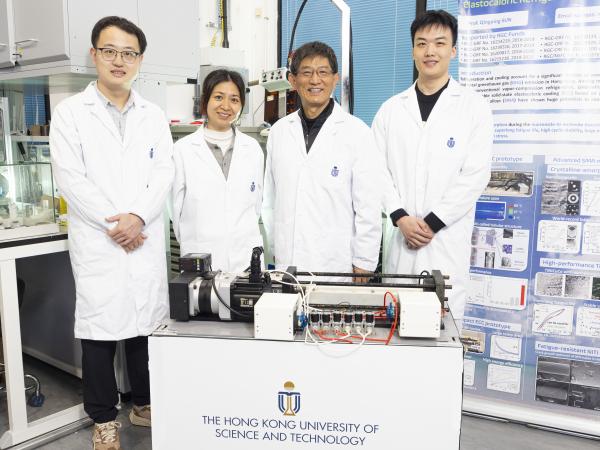

The study was conducted by Professors Sun Qingping and Yao Shuhuai, along with Dr. Zhou Guoan (Postdoctoral Research Associate), Li Zexi (MAE PhD student), Zhang Lingyun (Guangdong Eco-engineering Polytechnic, 2020 MSc graduate), and Prof. Hua Peng (Harbin Institute of Technology, 2019 PhD graduate).