The rapid rise in demand for electric vehicles (EVs) and battery storage has positioned batteries as one of the fastest-growing clean energy technologies globally. However, this growth brings sustainability challenges and an increasing need for critical minerals to support production.

A report by the International Energy Agency (IEA), titled ‘EV Battery Supply Chain Sustainability’, examines the emissions linked to batteries throughout their supply chain and lifetime. It highlights strategies to reduce emissions, emphasising that EVs already provide substantial global emissions reductions compared to internal combustion engine (ICE) vehicles. Improving battery supply chain sustainability—particularly through recycling—can amplify these benefits while reducing reliance on new critical minerals.

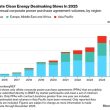

Under current policies, global battery demand is expected to quadruple by 2030 and increase more than sevenfold by 2035. Emerging markets and developing economies (EMDEs) beyond China are projected to play a growing role, with their share of global demand rising from 3% in 2023 to 10% by 2030. Investments in Europe, North America, and other EMDEs are set to diversify battery production.

A life cycle analysis reveals that emissions from a medium-sized battery electric vehicle are, on average, half those of a comparable ICE vehicle. The emissions gap is even more pronounced in countries like the UK and Chile, where reductions exceed 60%, compared to 20% in India.

Although battery-related emissions are not the largest contributor to an EV’s life cycle emissions, reducing these emissions remains essential. Key strategies include electrifying production processes, enhancing energy density in batteries, and expanding the use of recycled materials.

Recycling will be critical to managing the expected surge in end-of-life batteries. By 2050, effective recycling could reduce lithium and nickel demand by 25% and cobalt demand by 40%, according to climate-aligned scenarios. Scaling up recycling facilities and increasing collection rates of end-of-life batteries will be vital to achieving these reductions.

From 2035 onwards, the rapid growth of end-of-life EV batteries will further elevate the need for robust recycling systems. Recycling not only minimises reliance on new critical minerals but also supports circular economies.

Second-hand EVs could significantly boost electric mobility in EMDEs beyond China. However, ensuring sustainable end-of-life strategies for these vehicles and their batteries is crucial. Strengthened international cooperation is necessary to support the trade of second-hand EVs, establish effective recycling frameworks, address disposal challenges sustainably, and policy recommendations for a Sustainable Future.

The IEA report concludes by calling on policymakers to take comprehensive action to address the challenges of EV battery sustainability. Key recommendations include scaling up recycling initiatives and facilities to manage the growing number of end-of-life batteries and reduce reliance on primary critical minerals. The report also highlights the importance of diversifying battery production and supply chains to mitigate risks and foster resilience. Additionally, it underscores the need for international collaboration to support the trade of second-hand EVs while ensuring effective end-of-life strategies for their batteries. Finally, the report advocates for innovations aimed at enhancing battery performance and further reducing emissions, emphasising the pivotal role of technology and research in achieving these goals.