Researchers from UCLA’s Institute for Carbon Management have developed a method that could virtually eliminate the carbon dioxide emissions from cement production, a process responsible for nearly 8% of global CO2 emissions. The new approach, detailed in a study published in ‘Sustainable Chemistry and Engineering’, offers a cost-effective solution that can be integrated into existing cement production systems, potentially revolutionising the industry’s carbon footprint.

Ordinary Portland cement, the most widely used type, is a critical material for modern construction but comes with a significant environmental cost. The production process involves heating limestone in fossil fuel-powered kilns, emitting nearly 1 kilogram of CO2 for every kilogram of cement produced. About 60% of these emissions result from the chemical breakdown of limestone, while 40% comes from burning fossil fuels to heat the kiln.

The energy demand is also enormous, with the production of just one metric ton of lime requiring approximately 1.4 megawatt-hours of energy, enough to power 1.5 American homes for a month.

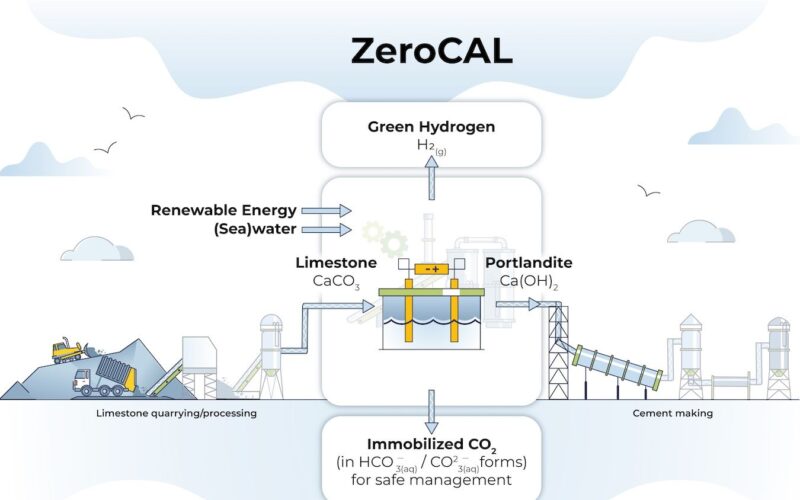

The UCLA team, led by Gaurav Sant, has developed the “ZeroCAL” method, which uses calcium hydroxide—a zero-carbon precursor for lime and cement production—rather than limestone. When heated, calcium hydroxide emits only water vapor instead of CO2. By dissolving limestone in a solution and using electrochemical processes, the researchers were able to produce calcium hydroxide without the associated carbon emissions.

This innovative process could reduce cement-related CO2 emissions by 98%. In addition to clean lime, ZeroCAL produces useful byproducts like hydrochloric acid, baking soda, and hydrogen gas, which could power the kilns, further reducing the environmental impact.

“The ZeroCAL approach offers an elegant solution to eliminate carbon dioxide emissions associated with the process of cement production,” said Sant, the study’s corresponding author and the Pritzker Professor of Sustainability at UCLA Samueli. “First, it addresses the carbon emissions resulting from limestone’s decomposition while providing clean hydrogen and oxygen to heat the cement kiln. Second, it enables onsite decarbonization while making use of existing kilns and limestone feedstocks without having to build separate carbon-capture and storage facilities.”

While the process currently requires more energy than traditional methods, ongoing research aims to reduce energy consumption and improve efficiency. The team is also exploring using water-rich locations, such as coastal or river-adjacent cement plants, to meet the water needs of the process.

UCLA is already working with Ultratech Cement Limited, India’s largest cement manufacturer, to build a demonstration plant that will produce several metric tons of lime daily using the ZeroCAL process.

“It has become crystal clear that mitigating climate change demands urgent, paradigm-shifting actions across many areas to decarbonize our society,” said study co-author Fabian Rosner, an assistant professor of civil and environmental engineering at UCLA Samueli. “We believe the ZeroCAL process offers a unique pathway to enable accessible and rapidly scalable decarbonization of cement production in a way we have not previously considered.”

The researchers believe the ZeroCAL method could have far-reaching implications, not just for cement but also for steel production, which could use low-carbon lime as a key ingredient. The research was funded by several prominent organizations, including the Chan Zuckerberg Initiative, Shell, and the U.S. Department of Energy.

With this innovative approach, UCLA researchers hope to lead a paradigm shift in how industries address climate change, offering scalable solutions to decarbonize some of the most carbon-intensive sectors in the world.

In addition to Sant, ICM authors of the study include first author Adriano Leão and ICM associate directors David Jassby, professor of civil and environmental engineering at UCLA Samueli, and Dante Simonetti, associate professor of chemical and biomolecular engineering at UCLA Samueli.

The other authors are from the Technical University of Munich in Germany, UC Davis and the UCLA startup Equatic Inc. Sant and Jassby are both members of the California NanoSystems Institute at UCLA, and Sant holds an additional faculty appointment in materials science and engineering.