Rolls-Royce is driving the development of methanol-fuelled solutions to support the maritime industry’s transition towards sustainable propulsion systems. With shipping responsible for approximately 2.5% of global CO₂ emissions, the company is focusing on methanol as a viable alternative due to its energy efficiency and compatibility with existing infrastructure.

Methanol’s liquid state simplifies storage and distribution, allowing it to be handled using current facilities with minimal modifications. Unlike ammonia, methanol is less hazardous and can be used in both combustion engines and zero-emission fuel cells, making it a flexible alternative for marine applications.

As part of its sustainability strategy, Rolls-Royce’s Power Systems division is preparing to certify its mtu Series 2000 and Series 4000 marine diesel engines for EN15940 synthetic diesel fuels, including Hydrotreated Vegetable Oil (HVO), from early 2023. This move is expected to cut CO₂ emissions by up to 90% compared to conventional fossil diesel.

Denise Kurtulus, head of the mtu marine propulsion business at Rolls-Royce Power Systems, sees green methanol as central to the industry’s decarbonisation efforts. “Green methanol has the potential to shape the energy transition in marine propulsion systems,” she said.

The global shipping sector aims to become climate-neutral by 2050, a significant challenge for an industry that consumes vast amounts of fossil fuel. Methanol offers a promising solution, particularly when produced using renewable electricity.

While methanol combustion still emits CO₂, green methanol is created through a process that captures CO₂ from the atmosphere, ensuring a net-zero impact. However, it has only around half the energy density of diesel, requiring larger fuel tanks. Despite this, methanol remains easier to handle than alternatives such as liquid natural gas (LNG), as it does not require refrigeration. Additionally, it is biodegradable and less explosive than LNG or hydrogen, reducing environmental risks in the event of an accident.

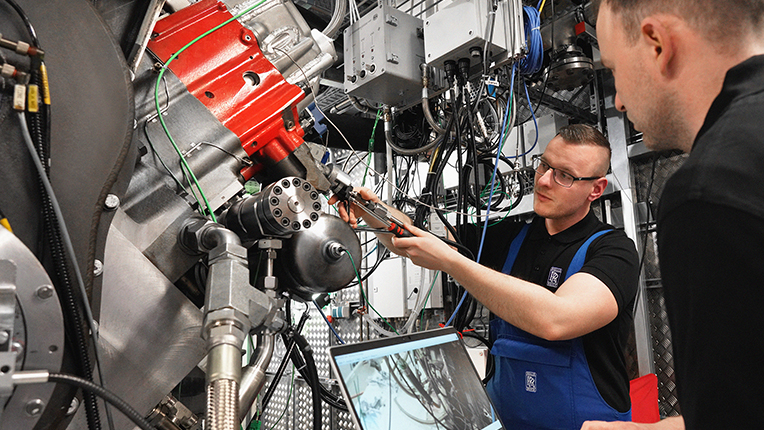

Rolls-Royce engineers are currently testing methanol combustion in a technology demonstrator and developing both single-fuel methanol engines and dual-fuel engines capable of running on both diesel and methanol.

“In the long term, we see pure methanol single-fuel engines as the best solution,” Kurtulus explained. However, she acknowledged that dual-fuel engines will play an important role in the medium term. “We see dual-fuel engines primarily as a bridging technology until green methanol is available across the board. However, the length of this bridge varies depending on the application.”

Certain vessels, such as globally operating yachts, may rely on dual-fuel systems for longer, whereas ferry and tugboat operators—who operate within known port infrastructure—could transition more quickly to methanol-only propulsion.

The shipping industry’s transition to methanol-fuelled vessels is already gaining traction. Danish shipping giant Maersk has introduced its first methanol-powered container ship and has placed orders for over 20 more. As demand rises, green methanol production is also increasing.

The world’s first commercial e-methanol production facility opened in Kassø, Denmark, in early 2025, with an annual production target of 35,000 tonnes. In Anyang, China, a commercial-scale plant has been producing up to 110,000 tonnes of CO₂-derived methanol annually for more than two years, using emissions recovered from lime production. Meanwhile, in Germany, a pilot facility has been producing green methanol since November 2023, using a process that is considered particularly cost-efficient.

While green methanol presents a viable pathway to reducing maritime emissions, industry experts acknowledge that no single solution will dominate the future of marine propulsion. Instead, a combination of renewable energy-based technologies, including methanol-powered engines, will be required to drive the industry towards a low-carbon future.